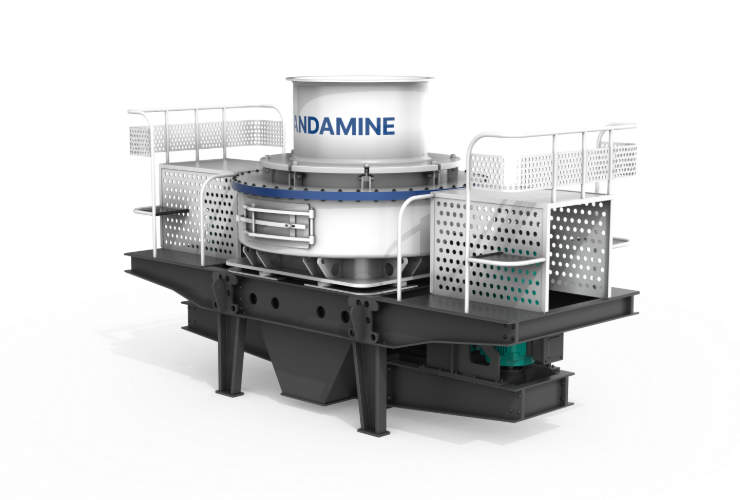

ANDAMINE Vertical Shaft Impactor((VSI)) is an ideal option for third or fourth stone crusher. This type crusher is widely used in the shaping of fine-grained aggregates during stone production and as the machine of made sand in road construction, building construction, and concrete batching plants, etc.

![]()

Feeding Size:

30-55mm

![]()

Finished Product:

0-4.75mm

![]()

Processing capacity:

60-480t/h

VSI Crusher In Stone Crushing Plant

ANDAMINE has developed stationary and mobile sand-making plants for crushing limestone, basalt, quartz, marble, granite, gravel, basalt, construction wastes, etc. We provide customized solutions for every project situation.

- Stationary Sand-making Plant

- Capacity: 70-1200 t/h (customizable)

- Crushing Materials: River pebbles, granite and even hard mineral rocks (iron ore), etc

- Configuration: jaw crusher + fine crushing compound cone crusher + vsi crusher + vibrating feeder + vibrating screen + belt conveyors

- Advantages: High Production Capacity | Versatile Output Sizes | Diverse Applications

Suitable for long-term projects with varying locations and durations.

Get A Quote >

- Mobile Sand-making Plant

- Capacity: 50-450 t/h (customizable)

- Configuration: vsi crusher + vibrating screen + belt conveyors

- Application: Designed for small and middle size project, which needs often moves.

- Advantages: It is more flexible and cost-effective, with time-saving advantages in disassembly, transportation, and installation.

Get A Quote >

Global Projects

ANDAMINE has exported crushing plants in 100+ countries, providing customers with versatile and ideal crushing plant solutions.

Crushing and Screening Plant for the paper industry in Indonesia

Raw Material: Limestone

Capacity: 200 TPH

Finished Product(mm): 5-10, 20-25

Configuration: Vibrating Feeder, Jaw Crusher, Impact Crusher, Vibrating Screen, etc.

Application: Quarry

Get A Quote >

Crushing and Screening Plant Running Well In Malaysia

Raw Material: Cobblestone

Capacity: 350TPH

Finished Product(mm): 0-5-10-30mm

Configuration: Vibrating Feeder, Jaw crusher, Impact Crusher, Vibrating Screen, etc.

Application: Road paving

Get A Quote >

ANDAMINE Service

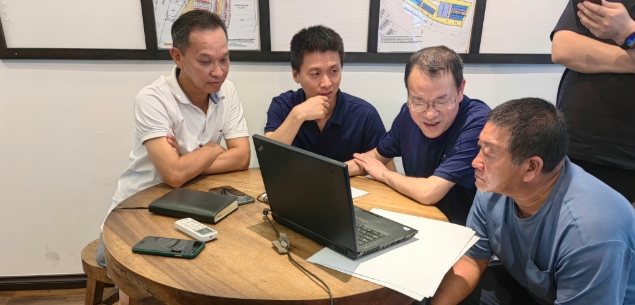

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.