Different Types of Stone Crusher

ANDAMINE offers a comprehensive range of crushers, including cone crushers, jaw crushers, impact crushers, vertical shaft impact crushers. These machines are extensively used for primary, secondary, and tertiary hard-rock crushing in stone-processing plants and sand-making facilities.

Jaw Crusher

The jaw crusher is primarily utilized for coarse and medium crushing and is widely employed across various industries, including mining, metallurgy, building materials, highways, railways, water conservancy, and chemical industries.

Applicable materials: river pebble, granite, basalt, iron ore, quartzite and other medium-hard hard rocks.

Capacity:20-1200t/h

Max Feeding Size:<680

Output Size:3-60mm

Get A Quote >

Cone Crusher

Cone crushers are utilized in the secondary and tertiary stages of crushing. They are specifically designed for processing ores and rocks with medium to high hardness.

Applicable materials: suitable for medium and fine crushing of basalt, river pebbles, granite, quartzite, metal ores and other high hardness materials.

Capacity:50-1200t/h

Max Feeding Size:<350mm

Output Size:3-60

Get A Quote >

Impact Crusher

An impact crusher is suitable for mining, construction, and recycling. It efficiently handles medium to low hardness materials and produces uniform particle sizes.

Applicable materials: various ores such as river pebble, granite, iron ore, limestone, slag, quartzite, construction waste, sand and gravel aggregates, etc.

Capacity:20-900t/h

Max Feeding Size:<700

Output Size:5-180mm

Get A Quote >

VSI Crusher

The vertical shaft impact crusher, also known as the VSI sand making machine, boasts high-efficiency performance and plays an irreplaceable role in fine crushing applications for various ores.

Application Artificial sand making. It is used in the shaping of fine-grained aggregates.

Capacity:60-480t/h

Max Feeding Size:30-55mm

Output Size:0-4.75mm

Get A Quote >

Different Combination of Stone Crusher

ANDAMINE’s stone crusher can be applied to a variety of aggregate production lines, such as stones of different hardness, different productivity, different output sizes, etc. ANDAMINE has provided our customers with customized aggregate production lines to produce high-quality aggregates. If you plan to invest in a crushing line, or plan to transform your existing production line, please contact us.

Jaw Crusher + Feeder

Jaw + Cone Crusher

Jaw + Cone Crusher

Jaw + Impact Crusher

Jaw + VSI Crusher

Impact Crusher +Screen

20-30t/h Small Mobile Crusher For Aggregate Primary Crushing

- Application: Small-scale crushing work or construction waste processing, suitable for all kinds of stone.

- Advantages: Easy to move on the site. Simple structure and low cost.

50-100t/h Mobile Crusher For Aggregate Primary and Secondary Crushing

- Application: Mainly for medium-small construction projects.

- Advantages: One set crushing equipment equals a complete crushing production line. The production line is short and the investment cost is low.

100-150t/h Mobile Crushing Plant For Supplying Aggregates to Concrete Batching Plants

- Application: Produce aggregates of different sizes to meet the supply of raw materials for concrete batching plants

- Advantages: Two set of mobile crushing plants form a complete production line, completing the work from coarse crushing to fine crushing.

150-200t/h Mobile Crushing Plant For Construction Waste Recycling

- Application: It can process construction waste, such as concrete waste and asphalt waste, and the finished products can be used for paving roads, making prefabricated concrete parts, etc.

- Advantages: The impact crusher has high crushing efficiency and good finished product particle shape. It is suitable for crushing a variety of materials, including concrete, bricks, asphalt and other construction waste.

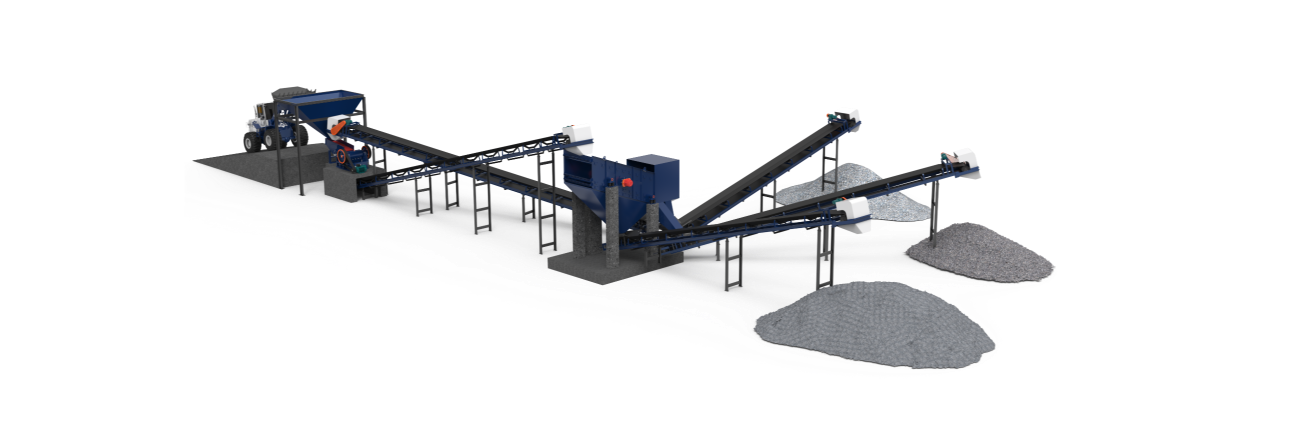

200-300t/h Stone Crushing Plant for Making Artificial Sand

- Aggregate Usage: Suitable for medium building, bridge, road construction projects, and concrete production.

- Advantages: The combination of primary jaw crusher and secondary jaw crusher can process a wider range of materials and improve production efficiency.

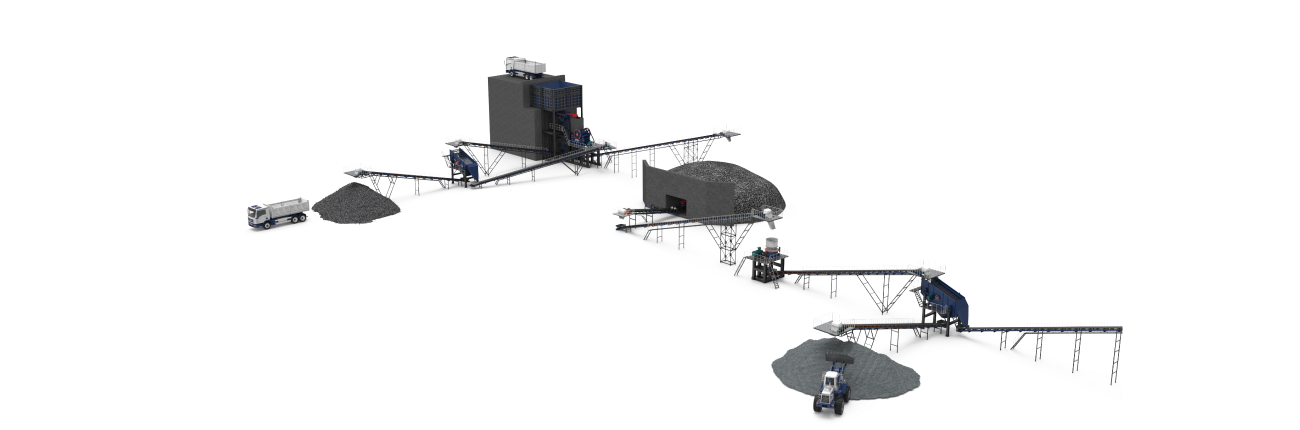

600t/h Stone Crushing Plant for Aggregate Selling

- Aggregate Usage: Can be used in large quarries and mines.

- Advantages: A variety of discharge sizes, high crushing efficiency. A transfer bin is set up at a crushing station to buffer and ensure even material feed, enhance production efficiency, reduce equipment wear, and handle supply contingencies.

Crushing Flow

Through the following process, you can clearly see that the raw materials go through primary crushing, secondary crushing, and finally go through the sand making machine and sand washing machine to produce high-quality sand. ANDAMINE can provide you with a customized full set of aggregate production lines. Welcome to contact us for exclusive solutions.

Stone Crusher Application

Through the following process, you can clearly see that the raw materials go through primary crushing, secondary crushing, and finally go through the sand making machine and sand washing machine to produce high-quality sand. ANDAMINE can provide you with a customized full set of aggregate production lines. Welcome to contact us for exclusive solutions.

Building Materials Production

Stone crushers are used to crush large stones into smaller pieces, which are then used as raw materials in the production of various building materials such as concrete, bricks, and paving stones.

Aggregate for Concrete Mixing Plants

In concrete batching plants, stone crushers are utilized to provide the necessary aggregate material, which is a crucial component in the production of concrete.

Construction Waste Recycling

Stone crushers play a vital role in recycling construction waste. They can crush demolition debris, such as concrete and bricks, into reusable material for new construction projects.

Artificial Sand Making

Stone crushers are used in the process of producing artificial sand by crushing rocks and stones. This sand is often used in construction projects where natural sand is either not available or too expensive.

ANDAMINE Global Projects

Through the following process, you can clearly see that the raw materials go through primary crushing, secondary crushing, and finally go through the sand making machine and sand washing machine to produce high-quality sand. ANDAMINE can provide you with a customized full set of aggregate production lines. Welcome to contact us for exclusive solutions.

150t/h Mobile Jaw Crusher Plant Successfully Installed in Honduras

Stone Materials: River Stone

Customer’s Needs: Seeking suppliers with stable quality and good after-sales service.

Solution: Provide customized solutions according to customer’s site and output requirements.

Get A Quote >

150t/h Mobile Cone Crusher Plant Successfully Installed in Honduras

Stone Materials: River Stone

Customer’s Needs: A secondary mobile crushing station is needed to process the aggregate produced by the mobile jaw crusher.

Solution: Provide customized mobile cone crusher according to customer’s site and output requirements.

Get A Quote >

80t/h Cone Crusher Plant in the Philippine

Stone Materials: Volcanic Rock

Customer’s Needs: Crush the stones into suitable sizes to increase sales profits.

Solution: The 80-ton cone crusher equipment crushes smaller particles and can better meet customer needs.

Get A Quote >

600t/h Cone Crusher Plant is Running in Malaysia

Stone Materials: Cobblestone

Customer’s Needs: The customer is worried about the cost performance and the follow-up service can not keep up

Solution: ANDAMINE has a local office in Malaysia and can go to the customer’s site at any time, and has sent engineers on site to help the customer’s long-term operation

Get A Quote >

ANDAMINE Service

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.