Benchmark Case of Mobile Crushers

Wanted to crush granite into 5-20mm aggregates to supply their 35m³/h concrete plant, reducing reliance on external suppliers.

1. Hard Material Wear: Competitor crushers wore out quickly (liner replacements every 3 weeks).

2. Buying aggregates from external suppliers added costs.

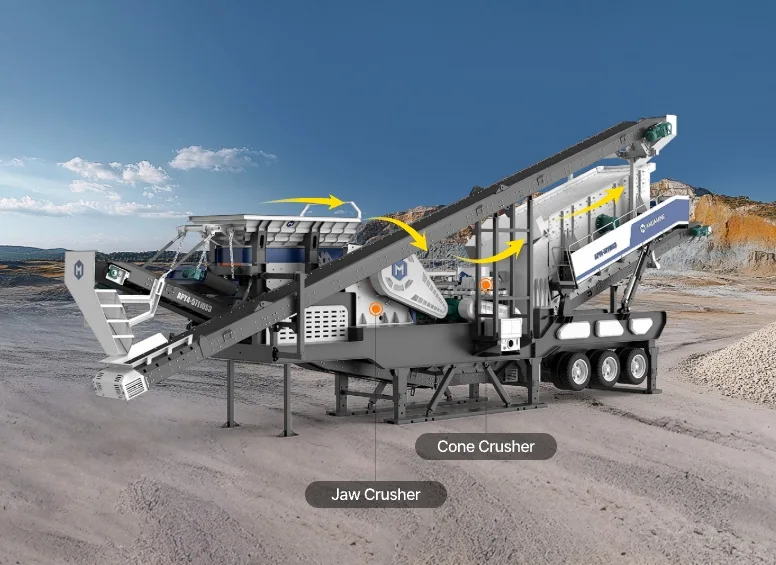

1. Compact 4-in-1 structure reduces operating costs: Automatically feeding, primary crushing(jaw crusher), secondary crushing(cone crusher) and screening on-site;

2. Hard-rock optimized crushing chamber with premium wear-resistant components;

– Jaw Crusher (Primary): Handled large and hard granite blocks (≤650mm);

– Multi-Cylinder Hydraulic Cone Crusher (Secondary): Produced well-shaped 5-20mm aggregates;

The operating costs of this mobile crusher are lower than we expected, and the aggregates it produces fully meet our concrete batching plant’s material requirements.

Hot Selling Mobile Crusher Models

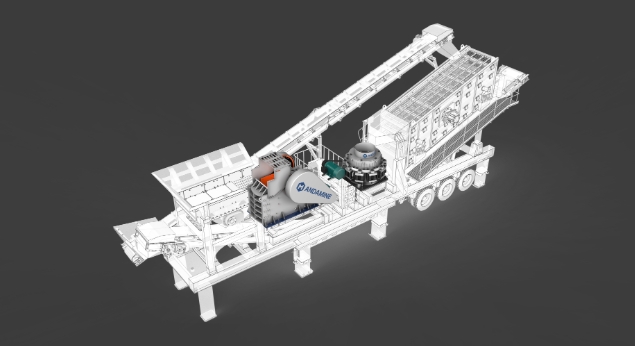

The ANDAMINE APY4-S and APY3-F mobile crushers are modular crushing systems that function as complete production lines in a single unit, delivering maximum return on investment while maintaining low operational costs. These two versatile models are designed to handle approximately 90% of market crushing applications, making them the ideal choice for most customers seeking efficient and cost-effective crushing solutions.

APY4-S Mobile Crusher and Screen Plant

Capacity: 30-200 T/H

Output Size(mm): 5-80

Max. Feeder Size(mm): <500

- Main Crusher: Jaw Crusher + Cone Crusher

- Raw Materials: Hard & soft stone, granite, limstone, river stone, copper ore, iron ore, etc.

- Advantages:

1. This 4 in 1(feeding, primary crushing, secondary crushing, and screening) mobile crusher combines of vibrating feeder, jaw crusher, cone crusher and vibrating screen.

2. Lower investment, saving area, and high rate of investment return.

3. The vibrating feeder adopts frequency conversion control(Remotely controlled), which can adjust the feeding amount of the feeder according to different situations.

Get A Quote >

APY3-F Mobile Impact Crusher Plant

Capacity: 50-350 T/H

Output Size(mm): 5-100mm

Max. Feeder Size(mm): <600

- Main Crusher: Impact Crusher

- Raw Materials: Medium-hard materials: limestone, concrete, asphalt wastes, etc.

- Advantages:

1. 3 in 1(Auto feeding, crushing, and screening)

2. Impact crusher: large crushing ratio and good particle shape.

3. Especially used for crushing concrete construction waste.

4. Equipped with European version of high cavity impact crusher, which has high crushing efficiency and versatility.

Get A Quote >

APY2-J Mobile Jaw Crusher Plant

- Capacity: 50-400 T/H

- Max. Feeder Size(mm): <720

- Output Size(mm): 5-180

- Main Function: Feeding and Crushing

- Raw Materials:

Hard and Medium-hardness rocks, limestone, granite, basalt, gold ore, iron ore, etc.

Get A Quote >

APY2-C Mobile Cone Crusher Plant

- Capacity: 100-310 T/H

- Max. Feeder Size(mm): <300

- Output Size(mm): 3-60

- Main Crusher: Cone Crusher

- Raw Materials:

Hard and ultra-hard stone: granite, basalt, cobblestone, etc.

Get A Quote >

Raw Materials & Application

Raw material:

Granite, Limestone, Gold Ore, Copper Ore, Iron Ore, Concrete Waste, Basalt, etc.

Areas of application:

Mobile crushing plants can be used to crush a variety of materials, such as iron ore, copper ore, limestone, granite, etc. Therefore, mobile crushing plants are widely used in quarries, commercial concrete, engineering construction, and construction waste fields, etc.

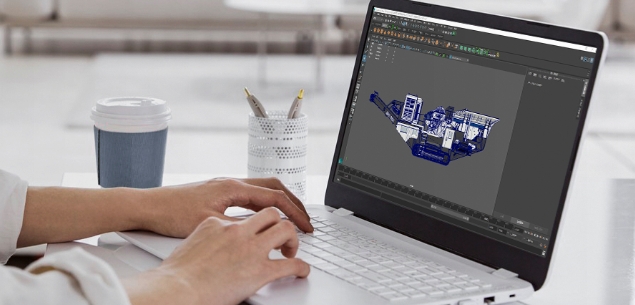

Smart Mobile Crusher Starts with IOT: Less Downtime, More Profit!

Features of Mobile Crusher

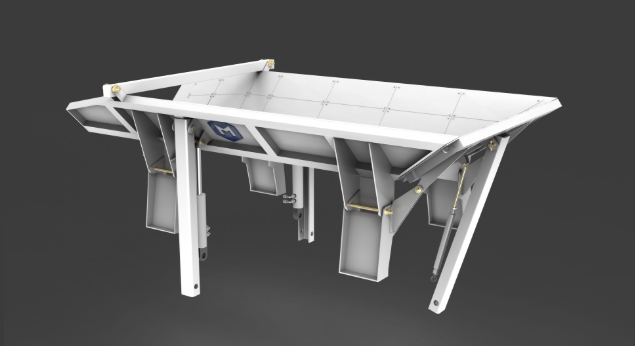

Large Volume Feeding Hopper

1. Large-Capacity Hoppers – Both primary and secondary crushers feature high-volume hoppers with double-layer reinforced side plates for enhanced durability;

2. Efficient Feeding System – The oversized hopper design enables easy loading and maintains consistent material flow for stable operation;

Free-foundation Installation

1. Free-Foundation Design – Integrated outriggers and steel support plates eliminate concrete foundations, reducing costs and setup time while ensuring operational stability;

2. Fast Deployment – The widened ground contact area lowers bearing capacity requirements, enabling immediate operation upon arrival at the site;

Modular Design

1. Modular & Universal Design – Features high structural strength and excellent versatility for flexible operations;

2. Maximized Versatility – Equipment with the same capacity can switch between models by replacing only a few components;

3. Quick Production Adjustment – Simply change the main machine to adapt to different materials;

Intelligent Operating System

1. Integrated Control System – one-button start, can be operated by PLC touch screen or button, improve production efficiency;

2. IOT Remote Monitoring System – real-time monitoring of equipment operation status, automatic reminder of maintenance, and reduce failure rate;

3. Intelligent Feeding – the feeder is equipped with remote control, and the batching speed can be adjusted to ensure production continuity;

Crushing Flow

Global Projects Application

ANDAMINE mobile crushers had reached to 100+ countries, and we have provided our customers with versatile and high-efficienct crushing and screening solutions. These crushing plants have been exported to various countries, for example: Tanzania, Honduras, Jamaica, Qatar, Saudi Arabia, Oman, Mongolia, Fiji, Kuwait, the Philippines, Malaysia, Indonesia, etc. Welcome you to contact us for more details.

Mobile Cone Crusher Plant – Granite Aggregates Selling

Capacity: 150T/H

Finished Product(mm): 5-10, 10-20

Configuration: Vibrating Feeder, Cone Crusher, Screen Machine, PLC Control Box, etc.

Feature: PLC control with display, one-button start, remote monitoring, bearing temp measurement, start-stop function

Customer’s Feedback: I am very grateful to the engineers of ANDAMINE for coming to my construction site and helping me complete the installation of the mobile crushing station. Now this crushing station is running well and the quality of the aggregates produced is also very high.

Get A Quote >

APY3-F 120t/h Mobile Impact Crushing Plant – Concrete Waste Processing

Max Feeding Size: 500mm, with a small amount of steel bars

Finished Product(mm): 0-1/4’-3/4′-1′-2′(0-5-19-25-50mm)

Advantages:

1. Heavy-duty chassis, 3-axle design, better quality, more stable travel

2. Self-unloading iron remover effectively removes iron from crushed material

3. Impact crusher with new tech, hydraulic clearance adjustment, ZWZ brand bearings

4. Partially raised raw material bin, hydraulically foldable, locking system for easy transport.

Get A Quote >

Mobile Screening Plant In the Philippines

Capacity: 80T/H

Raw Materials: Volcanic rock

Finished Product(mm): S1 3/4 G1 G2

Configuration: Vibrating Feeder, Vibrating Screen, etc. Application: For screening volcanic ash and volcanic rocks.

Get A Quote >

Mobile Jaw Crushing Plant in Honduras

Raw Material: River Stone

Capacity: 150T/PH

Finished Product(mm): 10-20, 20-25

Configuration: Feeder, Jaw Crusher, Screen Machine, PLC Control Box, etc.

Application: Aggregates Selling

Get A Quote >

ANDAMINE Service

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.

More Mobile Crusher Models

APY2-V Mobile Sand-making Machine

- Capacity: 60-400t/h

- Max. Feeder Size(mm): 30-55

- Output Size(mm): 0-4.75-30

- Main Configuration: Vibrating screen, VSI Crusher, PLC control box, etc.

Get A Quote >

APY2-F Mobile Impact Crusher

- Capacity: 60-350t/h

- Max. Feeder Size(mm): 300

- Feature: 2 in 1(crushing and screening)

- Main Configuration: Impact Crusher, Vibrating screen, PLC control box, etc.

Get A Quote >

APY-S Mobile Screening Machine

- Capacity: 65-400 T/H

- Max. Feeder Size(mm): <200

- Amplitude(mm): 8-12

- Main Configuration: vibrating screening, PLC control box, etc.

Get A Quote >

APYL Crawler Mobile Crusher

- Capacity: 50-300 T/H

- Max. Feeder Size(mm): <700

- Output Size(mm): 3-250

- Main Configuration: vibrating feeder, crusher machine, PLC control box, etc.

Get A Quote >

FAQs

What types of raw materials are suitable for the mobile crushing plant?

- Stone: Limestone, Granite, Marble, Basalt, River Pebbles, Shale, Coal, Pebbles, etc.

- Ore: Copper Ore, Iron ore, etc.

- Construction Wastes: Concrete Wastes, Bricks Wastes, etc.

What are the specific output size ranges that can be achieved?

- Customized output Size.

- 0-5mm; 5-10mm; 10-20mm; 20mm and above.