![]()

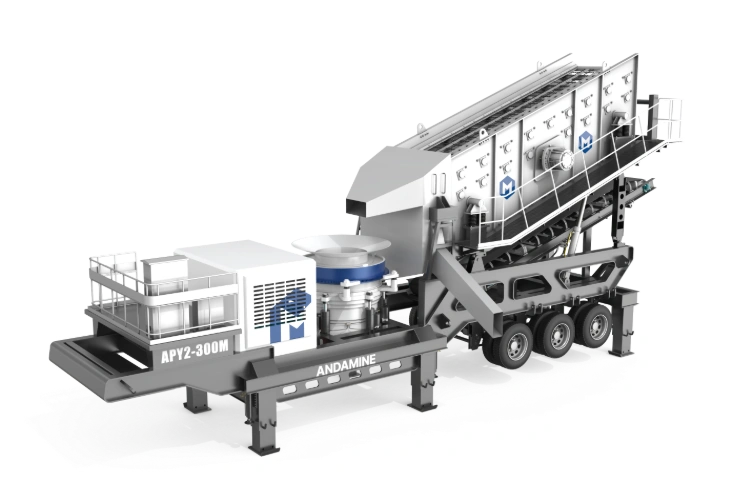

Capacity:

up to 310 T/H

![]()

Inlet opening:

180 mm

![]()

Final Particle Size:

3-60mm

Features

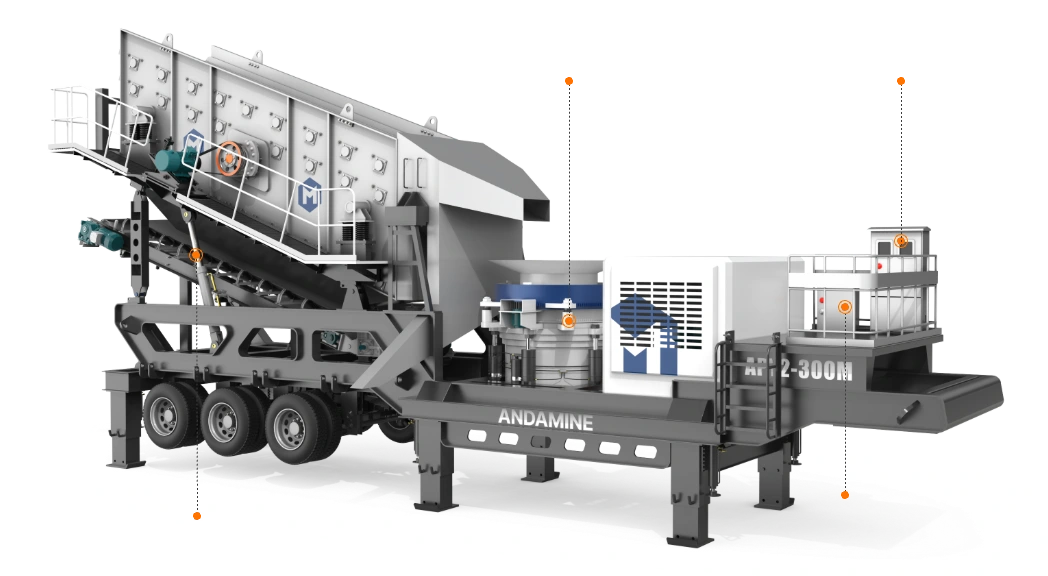

Intelligent operation promotes efficient production

Adopts imported brand Siemens PLC intelligent control system and touch screen; real-time monitoring of equipment operation status, automatic reminder of maintenance;

Integrated design allows you to no longer worry about the space of the site

integrates feeding, crushing, and screening, integrates crushing processes, and reduces operating costs;

Easy to operate, workers can get started quickly

Intelligent one click startup. Foundation-free installation;

Reliable cone crusher

The Cone crusher adopts an automatic control system, which is easy to operate, stable, reliable, high in efficiency and good in particle shape;

IOT remote monitoring system

Real-time monitoring of equipment operation status, automatic reminder of maintenance, and reduce failure rate;

Hydraulic Lubrication

Support leg adopts hydraulic lifting, equipped with synchronous valve, main engine bearing lubrication selection of centralized lubrication, equipped with automatic or mechanical fuel pump, Easy to operate, save manpower;

Integrated control system

One-button start, can be operated by PLC touch screen or button, improve production efficiency;

Specifications

| APY2-C Series Mobile Cone Crusher Specifications | ||||

|---|---|---|---|---|

| Models | APY2-300C-S1 | APY2-400C-S1 | APY-300C-S1 | APY2-660C-S1 |

| Power (kw) | 244 | 342.5 | 244 | 342.5 |

| Capacity (t/h) | 115-400 | 140-590 | 110-335 | 180-60 |

| Crusher Models | APC-300M | APC-400M | APC-440D | APC-660D |

| Max Feeding Size(mm) | 210 | 250 | 175 | 215 |

Global Projects Application

ANDAMINE stone crushing plants had reached to 100+ countries, and we have provided our customers with versatile and high-efficienct crushing and screening solutions. These crushing plants have been exported to various countries, for example: Tanzania, Honduras, Jamaica, Qatar, Saudi Arabia, Oman, Mongolia, Fiji, Kuwait, the Philippines, Malaysia, Indonesia, etc. Welcome you to contact us for more details.

ANDAMINE 100t/h Stationary Stone Crushing Plant In Tanzania

Order Time: January 20, 2025 Raw Materials: Limestone

What customers care about most: After-sales service, machine quality.

Application Field: Supply aggregate for own concrete batching plant using, saving cost for buying aggregate.

Configuration: Stationary Vibrating feeder+ Jaw crusher + Impact crusher+ Vibrating screen.

Get A Quote >

ANDAMINE 200t/h Stationary Stone Crushing Plant In Indonesia

Order Time: Dec, 2024 Raw Materials: Limestone

What the client wants to achieve: Need more crusher production lines. Produces large-sized limestone raw materials.

Application Field: For aggregate production and selling.

Configuration: Vibration feeder, jaw crusher, conveying belts, vibrating screen, etc.

Get A Quote >

350T/H Stone Crushing and Screening Plants For Cobblestone

Raw Material: Cobblestone Capacity: 350T/H

Finished Product(mm): 5-10, 10-20, 20-25

Configuration: Vibrating Feeder, Cone Crusher, Vibrating Screen, etc.

Application: Quarry

Get A Quote >

80t/h Cone Crusher Plant in the Philippines

Stone Materials: Volcanic Rock

Customer’s Needs: Crush the stones into suitable sizes to increase sales profits.

Solution: The 80-ton cone crusher equipment crushes smaller particles and can better meet customer needs.

Get A Quote >

600t/h Cone Crusher Plant is Running in Malaysia

Stone Materials: Cobblestone

Customer’s Needs: The customer is worried about the cost performance and the follow-up service can not keep up

Solution: ANDAMINE has a local office and can go to the customer’s site at any time, and has sent engineers on site to help the customer’s long-term operation

Get A Quote >