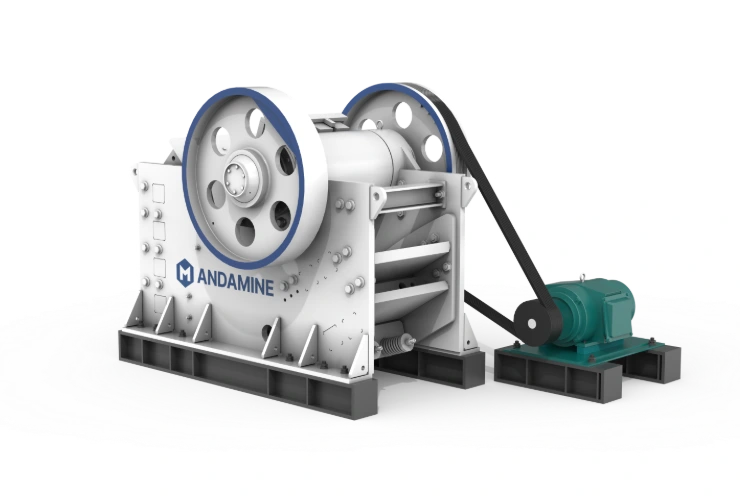

ANDAMINE Jaw crusher is used in primary or secondary crushing as the first process of stone crushing line. All kinds of ores whose compressive strength is not higher than 320Mpa. It is your preferred primary crusher, and it can be used for crushing various types of raw materials such as limestone, basalt, granite, marble, iron ore, coal, etc.

![]()

Feeding Size:

120-1000mm

![]()

Finished Product:

15-300mm

![]()

Processing capacity:

20-800t/h

Types of ANDAMINE Jaw Crushers

We can select a suitable jaw crusher for you, according to the size of raw materials, aggregate requirements, and site construction requirements. Most importantly, ANDAMINE crusher experts can also develop customized solutions for you.

APJ-E Jaw Crusher

- Capacity: 20-800t/h, Customizable

- Max Feeding Size: 130mm-1000mm; According to Model

- Motor Power: 5.5-220 kw; According to Model

- Description: Standard jaw crusher output particle size is large, usually 100-350mm, and secondary crushing is required; It can directly process bulk materials with a particle size of 1.2 meters.

- Features: Large crushing ratio, uniform product size, safe and reliable lubrication system.

Get A Quote >

APJ-V Jaw Crusher

- Capacity: 65-800t/h, Customizable

- Max Feeding Size: 420mm-1000mm; According to Model

- Motor Power: 75-250 kw; According to Model

- Description: European Type jaw crusher adopts the most advanced international crushing technology and manufacturing level, which is the first choice for crushing hardness and strong abrasive materials.

- Features: The discharge port adopts “wedge hydraulic adjustment device”, which is simpler and more reliable to adjust.

Get A Quote >

APJ-X Jaw Crusher

- Capacity: 8-95t/h, Customizable

- Max Feeding Size: 120mm-250mm; According to Model

- Motor Power: 15-75 kw; According to Model

- Description: Small jaw crusher is used in secondary crushing for medium and fine crushing after coarse crushing, so as to provide qualified feed material for the next production process.

- Features: Simple structure, reliable operation, low operating costs; Low noise, little dust.

Get A Quote >

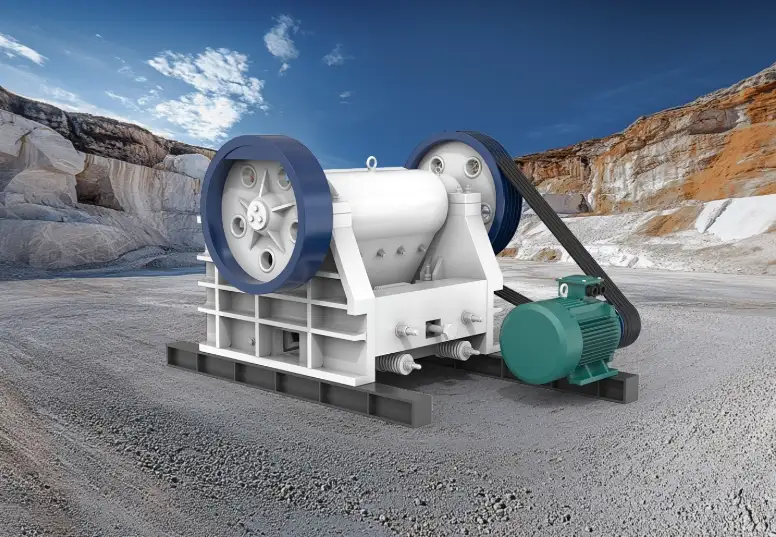

Jaw Crusher In Stone Crushing Plant

Jaw crusher forms a complete set of sand production line with the cone crusher, impact crusher, sand making machine, etc. It is widely used in mining, metallurgy, chemical industry, building materials, electricity, water conservancy transportation, etc.

- Type: Stationary crusher plant

- Capacity: 150tph (customizable)

- Crushing Materials: River pebbles, granite and even hard mineral rocks (iron ore), etc

- Configuration: jaw crusher + fine crushing compound cone crusher + vibrating feeder + vibrating screen + belt conveyors

- Advantages: Large crushing ratio and high production efficiency, which bring considerable economic benefits to you.

Get A Quote >

- Type: Mobile crusher plant

- Capacity: 200tph (customizable)

- Configuration: Vibrating feeder+ jaw crusher+compound cone crusher+vibrating screen+belt conveyors

- Application: It is suitable for short-term small and medium-sized projects, such as road, dam construction, etc.

- Advantages: It is more flexible and cost-effective, with time-saving advantages in disassembly, transportation, and installation.

Get A Quote >

Advantages of ANDAMINE Jaw Crusher

We can select a suitable jaw crusher for you, according to the size of raw materials, aggregate requirements, and site construction requirements. Most importantly, ANDAMINE crusher experts can also develop customized solutions for you.

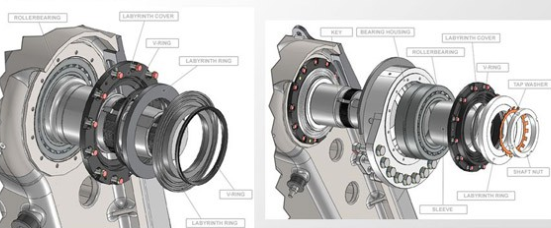

Good Quality Eccentric Shaft

ANDAMINE uses high carbon steel material in casting, and heat treatment process to improve its strength, toughness and wear resistance. Besides eccentric parts must be fine finishing and heat treatment, and the bearing lining is cast by Babbitt alloy.

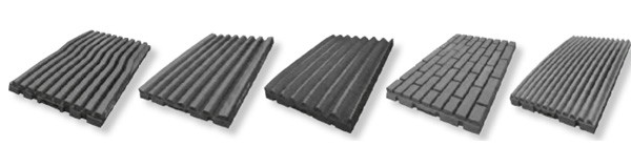

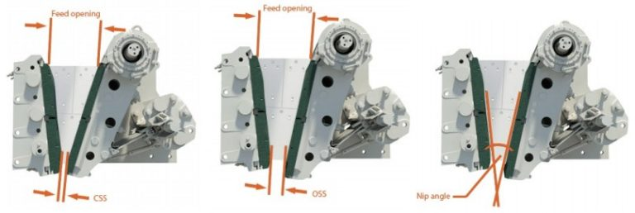

Variety Jaw Plate Shapes

A variety of jaw plate shapes are available, high crushing ratio, well-distributed final product size.

High Quality Plate Materials

To protect the jaw plate, we install wear-resistant liner on the surface of moving jaw and the stationary jaw. ANDAMINE uses high chromium cast iron on High manganese steel plate (Mn13, Mn13Cr2, Mn18Cr2). It significantly improves the jaw plate service life.

Notice:

Notice:

Due to the wear and tear of the jaw plate, the thickness of the jaw plate is reduced, the discharge port is enlarged, and the pressure of the medium crushing device is increased. Therefore, the discharge port must be adjusted.

Adjustment period: 5-10 days Replacement cycle: 3-4 months

Specifications

| Models | Inlet size (mm) | Max feeding size (mm) | Outlet size (mm) | Capacity (t/h) | Power (kW) | Overall size L×W×H (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|

| APJ-1575X | 150×750 | 120 | 18-48 | 45894 | 15 | 1380×1658×1025 | 3.5 |

| APJ-2575X | 250×750 | 210 | 25-60 | 13-35 | 30 | 1545×1667×1330 | 5 |

| APJ-2510X | 250×1000 | 210 | 25-60 | 16-52 | 30-37 | 1530×1992×1380 | 6.5 |

| APJ-2512X | 250×1200 | 210 | 25-60 | 20-61 | 37-45 | 1900×2192×1430 | 8.8 |

| APJ-3013X | 350×1300 | 250 | 20-90 | 25-95 | 55-75 | 1750×2320×1724 | 12.6 |

| Model | Inlet size (mm) | Max feeding size (mm) | Outlet size (mm) | Capacity (t/h) | Power (kW) | Overall size L×W×H (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|

| APJ-80V | 510×800 | 420 | 40-175 | 65-220 | 75 | 2500×1750×1950 | 7.5 |

| APJ-100V | 760×1000 | 640 | 70-200 | 150-350 | 90-110 | 3100×1980×2490 | 20 |

| APJ-106V | 700×1060 | 600 | 70-200 | 150-400 | 110 | 3450×1900×2490 | 13.5 |

| APJ-110V | 850×1100 | 720 | 70-200 | 190-450 | 160 | 3750×2280×2880 | 25 |

| APJ-125V | 950×1250 | 800 | 100-250 | 290-500 | 160 | 4870×2850×3570 | 36.7 |

| APJ-140V | 1070×1400 | 900 | 125-250 | 350-550 | 200 | 5100×3050×3790 | 45.3 |

| APJ-145V | 1100×1400 | 930 | 125-275 | 400-650 | 200 | 5300×3150×3890 | 53.8 |

| APJ-160V | 1200×1600 | 1000 | 150-275 | 500-800 | 250 | 5500×3250×3990 | 68.6 |

| Model | Inlet size (mm) | Max feeding size (mm) | Outlet size (mm) | Capacity (t/h) | Power (kW) | Overall size L×W×H (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|

| APJ-1575X | 150×750 | 120 | 18-48 | 45894 | 15 | 1380×1658×1025 | 3.5 |

| APJ-2575X | 250×750 | 210 | 25-60 | 13-35 | 30 | 1545×1667×1330 | 5 |

| APJ-2510X | 250×1000 | 210 | 25-60 | 16-52 | 30-37 | 1530×1992×1380 | 6.5 |

| APJ-2512X | 250×1200 | 210 | 25-60 | 20-61 | 37-45 | 1900×2192×1430 | 8.8 |

| APJ-3013X | 300×1300 | 250 | 20-90 | 25-95 | 55-75 | 1750×2320×1724 | 12.6 |

Global Projects

ANDAMINE has exported crushing plants in 100+ countries, providing customers with versatile and ideal crushing plant solutions.

Crushing and Screening Plant for the paper industry in Indonesia

Raw Material: Limestone

Capacity: 200 TPH

Finished Product(mm): 5-10, 20-25

Configuration: Vibrating Feeder, Jaw Crusher, Impact Crusher, Vibrating Screen, etc.

Application: Quarry

Get A Quote >

Crushing and Screening Plant Running Well In Malaysia

Raw Material: Cobblestone

Capacity: 350TPH

Finished Product(mm): 0-5-10-30mm

Configuration: Vibrating Feeder, Jaw crusher, Impact Crusher, Vibrating Screen, etc.

Application: Road paving

Get A Quote >

ANDAMINE Service

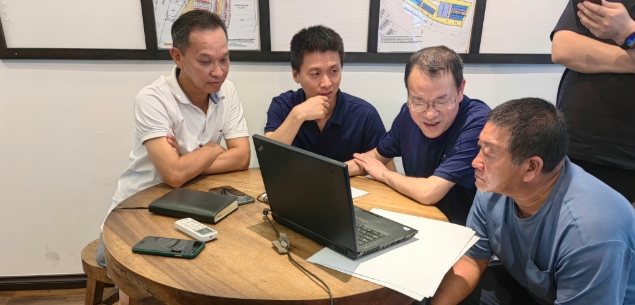

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.