ANDAMINE offers two highly efficient mobile crushing solutions: the wheel-type mobile crusher, designed for rapid road transportation with its tire-mounted system, making it ideal for projects requiring frequent relocation; and the crawler-type mobile crusher, built with a rugged tracked chassis to navigate challenging terrains like rocky or uneven surfaces with ease. Both crushers are engineered to handle a wide range of materials, including limestone, granite, construction waste, and minerals like gold, copper, and iron ore, making them perfect for demanding applications across the Middle East.

Whether you prioritize mobility or off-road capability, ANDAMINE provides the right crushing solution to maximize productivity in any environment.

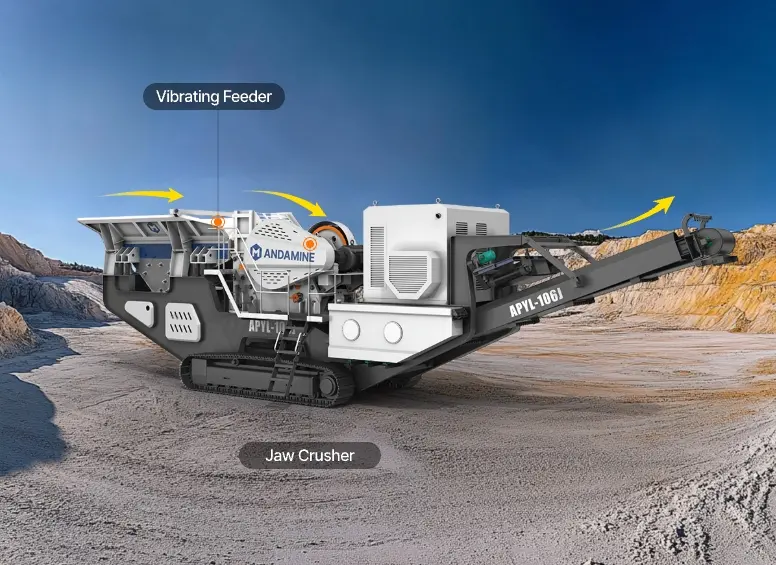

Discover Crawler Mobile Crusher Models

APYL2-J Mobile Jaw Crusher

Capacity: 80-415 T/H

Output Size(mm): 60-250

Max. Feeder Size(mm): <700

- Raw Materials: suitable for all kinds of rocks, limestone, granite, concrete waste, etc.

- Advantages:

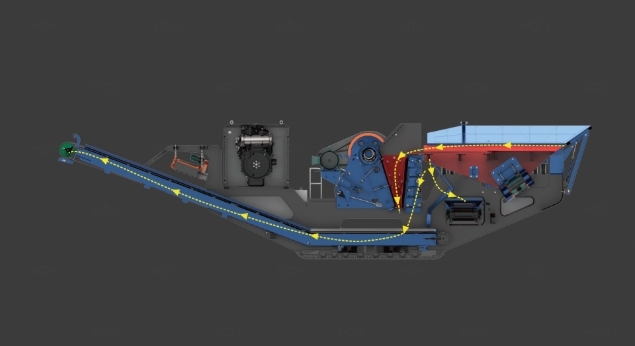

1. 2 in 1(feeding and crushing) mobile jaw crusher is suitable for use as a primary crushing line and is capable of processing most large-sized aggregates.

2. The hydraulic device is used to control the discharge port to adjust the output, and the output and fineness of the crusher can be flexibly controlled to meet different production and market demands.

3. Equipped with European version C series jaw crushing, large folding silo, pre-screening system, mainly used for coarse crushing materials, large feed particle size, wide discharge range, convenient transfer, high crushing efficiency.

Get A Quote >

APYL2-C Mobile Cone Crusher

Capacity: 100-310 T/H

Output Size(mm): 30-60

Max. Feeder Size(mm): <180

- Raw Materials: granite, limstone, river stone, copper ore, iron ore, etc.

- Advantages:

1. This 2 in 1(secondary crushing and screening) model combines cone crusher and vibrating screen. It is mainly for secondary crushing, suitable for medium and high hardness rocks.

2. Capable of handling most materials, especially hard rock, for example hard granite.

3. The crushing chamber types of cone crusher are divided into coarse, medium and fine types, and the product particle size adaptability is strong.

4. The main machine is equipped with cone crushing, laminating crushing, and equipped with large torque slow loading machine to ensure uniform feeding; Large crushing yield, and small wear.

Get A Quote >

APYL2-F Mobile Impact Crusher

- Capacity: 80-300 T/H

- Max. Feeder Size(mm): <600

- Output Size(mm): 5-200

- Main Function: Feeding and Crushing

- Advantages:

1. This 3 in 1(feeding, crushing and screening) model combines vibrating feeder, impact crusher and vibrating screen. It is a complete crushing production line.

2. Capable of handling most middle-hard materials, especially limestone.

3. Ideal for construction waste recycling, such as concrete waste, slags, etc.

4. Powerful good grain shape. High energy efficiency ratio.

Get A Quote >

APYL-S Mobile Screening Plant

- Driven Method: Remote Control.

- Capacity: 120-450 T/H

- Deck Quantity: 3

- Output Size(mm): 0-10, 10-20, 20-30, customized.

- Advantages:

1. Equipped with automatic folding belt machine, large processing capacity, can be used for fine screening of materials.

2. Suitable for all kinds of sand and construction waste after crushing finished material screening.

3. The overall transition is flexible, durable and reliable.

Get A Quote >

Raw Materials & Application

Raw material:

River pebbles, basalt, granite, limestone, copper ore, iron ore

Areas of application:

Mobile crushing plants can be used to crush a variety of materials, such as iron ore, copper ore, limestone, granite, etc. Therefore, mobile crushing plants are widely used in quarries, commercial concrete, engineering construction, and construction waste fields, etc.

Technical Features

Pre-screening Module

Using an independent pre-screening machine, the raw materials smaller than the finished products are pre-screened by the grate bar and enter the main belt conveyor (finished materials) or the side discharge belt conveyor (soil materi-als), which effectively reduces the workload of the crushing host and increases production capacity in disguise.

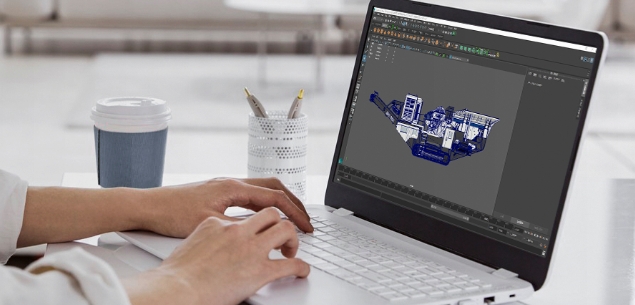

Intelligent Operating System

1. Integrated control system: one-button start, can be operated by PLC touch screen or button, improve production efficiency;

2. IOT remote monitoring system: real-time monitoring of equipment operation status, automatic reminder of maintenance, and reduce failure rate;

3. Intelligent feeding: the feeder is equipped with remote control, and the batching speed can be adjusted to ensure production continuity.

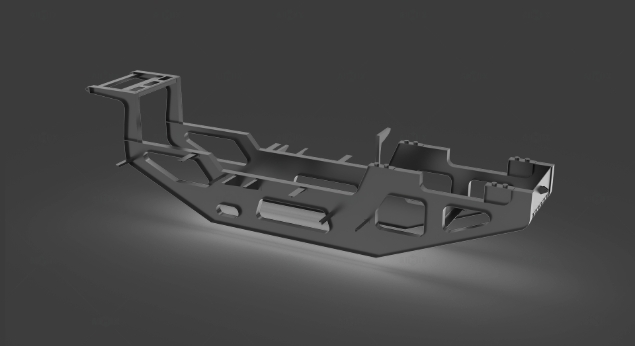

Heavy Duty Structure Design

The new generation of reinforced steel frame adopts a heavy-duty structural design and uses material with higher strength and better low-temperature performance. The overall frame has been strengthened in areas with high working stress and weak links of structural components through three-dimensional finite element analysis, making the whole machine more stable and have a longer service life during operation.

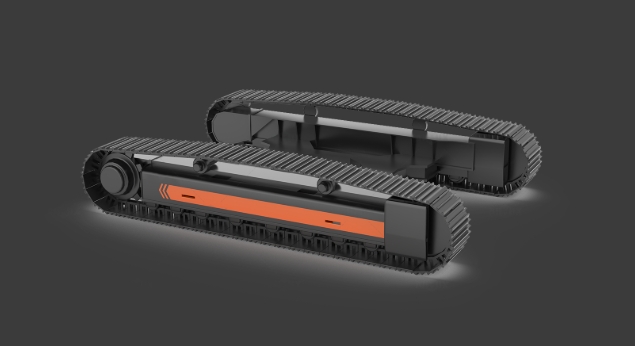

Track Chassis

The maximum driving torque on one side of the chassis is 80000NM, making it easy to turn on sandy ground and suitable for various harsh environments. The whole machine is operated by a well-known brand handheld wireless remote control, with a walking speed of 0.8km/hand a remote control distance of up to 100 meters.

Global Projects Application

ANDAMINE mobile crushing plants are usually used in quarries, construction projects, construction waste recycling, mining, etc. At present, our mobile crushing plant has been sold to many countries around the world, such as Saudi Arabia, Oman, Qatar, the Philippines, Malaysia, Indonesia, Honduras, etc. Our aim is not only to provide customers with high-quality and efficient crushing equipment, but also to provide customers with considerate services and help customers make their crushing projects profitable.

100-200T/H Crawler-type Mobile Crushing Plant Put Into use On-site

Raw Material: Limestone

Final Particle Size(mm): 5-10, 10-20, 20-40

Customer’s Application:

Quarry use. The customer’s quarry has large-sized stones which are not valuable. So the customer plans to use our mobile crushing station to crush them into small sizes and then sell them.

Get A Quote >

200T/H Crawler-type Mobile Crushing Plants Running Well In Malaysia For Road

Construction Project

Raw Material: Granite

Final Particle Size(mm): 80-100mm

Customer’s Application:

We highly recognize and thank your technical personnel for their professionalism during the installation of equipment on our construction site.

Get A Quote >

Tracked Crushing and Screening Plant Running Well In Malaysia

Raw Material: Cobblestone

Capacity: 150TPH

Finished Product(mm): 0-5, 5-10, 10-20, 20-25

Application: Road paving

Configuration:

Crawler Jaw Crusher, Crawler Cone Crusher & Crawler Screen Plant

Get A Quote >

ANDAMINE Service

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.