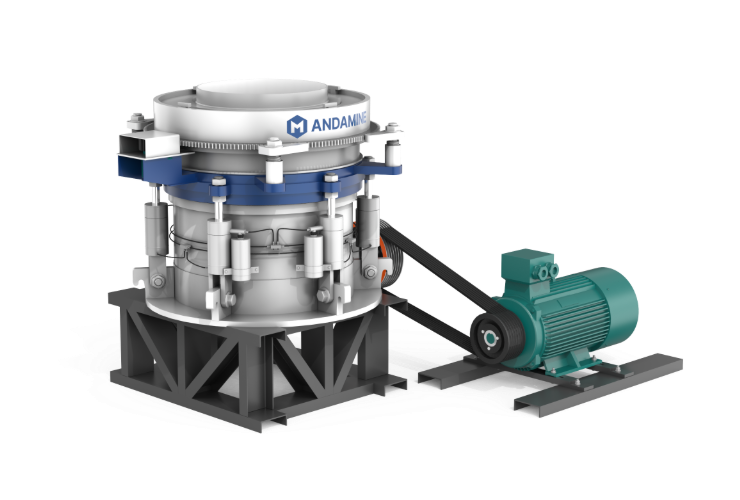

The cone crusher is an integral structure. Compared with other types of crushers (such as jaw crushers and impact crushers), its structure is simpler and the connection between components is relatively simple. The shape of the crushing chamber can be changed by adjusting the distance between the cone and the crusher shell to achieve the crushing requirements of different materials.

The crushing chamber is divided into three types: coarse, medium and fine, and the product particle size is highly adaptable, which can reduce the modification of the machine and the replacement of parts.

![]()

Feeding Size:

<350mm

![]()

Finished Product:

3-60mm

![]()

Processing capacity:

50-1200t/h

Types of ANDAMINE Cone Crushers

Cone crusher is ideal for crushing different stone and rock in quarry, mining, road construction, etc. It can also provide aggregate for concrete batching plant. ANDAMINE mainly provides the following four types of cone crushers to meet your different needs in aggregate size.

APC-M Multi-cylinder Hydraulic Type

- Capacity: 90-1200t/h, Customizable

- Inlet Size(mm): 20-353

- Min. Output Size(mm): 6

- Features:

1. Finished product have high-quality cubic shape;

2. Suitable for crushing various ores and rocks with medium and above hardness, such as limestone, iron ore, river pebbles;

3. Easy maintenance feature can ensure extraordinary high stability operation;

4. The hydraulic system is used to control locking, cavity cleaning, discharge port adjustment, overload and insurance, and the operation and maintenance and wear costs are low.

Get A Quote >

APC-D Single Cylinder Hydraulic Type

- Capacity: 48-500 t/h, Customizable

- Inlet Size(mm): 270

- Min. Output Size(mm): 6

- Features:

1. Widely used in medium and fine crushing and fine crushing;

2. suitable for crushing chrome ore, basalt, granite and other medium and high hardness materials;

3. Good particle size uniformity and cubic particle shape, which is conducive to construction sand making operations.

Get A Quote >

APC-C Compound Type

- Capacity: 18-655 t/h, Customizable

- Inlet Size(mm): 267

- Min. Output Size(mm): 6-64

- Features:

1. With springs and hydraulic cylinders;

2. Good product particle size composition, convenient maintenance;

3. Often used for medium and fine crushing

Get A Quote >

Cone Crusher In Stone Crushing Plant

ANDAMINE offers two crushing solutions: mobile and stationary. Both of them are suitable in quarry, mining, road construction, construction wastes disposable,etc.

- Type: Stationary crusher plant

- Capacity: 70-1200tph (customizable)

- Feature: High Production Capacity | Versatile Output Sizes | Diverse Applications

Suitable for long-term projects with varying locations and durations.

Get A Quote >

- Type: Mobile crusher plant

- Capacity: 100-450tph (customizable)

- Feature: Easily transportation and set up | High flexibility | Saving space;

Suitable for short-term projects with varying locations and durations.

Get A Quote >

Advantages of ANDAMINE Cone Crusher

We can select a suitable cone crusher for you, according to the size of raw materials, aggregate requirements, and site construction requirements. Most importantly, ANDAMINE crusher experts can also develop customized solutions for you.

Adjustable Discharge Opening

Cone crushers often have adjustable discharge openings, allowing operators to adjust the size of the output materials as needed.

Wide Discharging Size

Cone crushers have a broad range of discharge size capabilities, accommodating both fine and coarse materials. This versatility makes cone crushers suitable for various industries and applications.

Uniform Particle Size

Cone crushers are designed with special crushing chamber configurations and transmission principles to ensure a more uniform particle size distribution in the crushed output.

Notice:

Notice:

Due to the wear and tear of the jaw plate, the thickness of the jaw plate is reduced, the discharge port is enlarged, and the pressure of the medium crushing device is increased. Therefore, the discharge port must be adjusted.

Adjustment period: 5-10 days Replacement cycle: 3-4 months

Global Projects

ANDAMINE has exported crushing plants in 100+ countries, providing customers with versatile and ideal crushing plant solutions.

80t/h Stone Crusher Plant In The Philippines

Raw Material: Volcanic Stone

Crusher Model: Cone Crusher

Finished Product(mm): 5-10, 20-25

Configuration: Vibrating Feeder, Cone Crusher, Vibrating Screen, etc.

Application: The customer first bought a mobile screening plant from ANDAMINE, and later bought this cone crushing plant to crush and screen large-sized aggregates for sale.

Get A Quote >

Stationary Cone Crusher is Running in Malaysia

Raw Material: Cobblestone

Capacity: 600TPH

Finished Product(mm): 0-20

Configuration: Vibrating Feeder, Cone crusher, Vibrating Screen, etc.

ANDAMINE Service: ANDAMINE has a local office in Malaysia and can go to the customer’s site at any time, and has sent engineers on site to help the customer’s long-term operation.

Get A Quote >

Mobile Cone Crushing Plant Ready to be Shppied to Honduras

Raw Material: River Stone

Capacity: 150TPH

Finished Product(mm): 10-20, 20-25

Configuration: APC-M Cone Crusher, Vibrating Screen, PLC Control Box, etc.

Application: Road paving.

Get A Quote >

APC-75C Cone Crusher In Russia

Raw Material: Cobblestone

Capacity: 20-30TPH

Feeding Size(mm): <34mm

Finished Product(mm): <10mm

Application: Applied in crushing plant for road paving.

Get A Quote >

ANDAMINE Service

Project Consultant & Solution Offered

Project Consultant & Solution Offered

ANDAMINE professional engineer team can provide you with customized crushing plant solutions based on the basic conditions of your project, such as budget, raw materials, productivity, output size, etc.

On-site Installation & Training

On-site Installation & Training

ANDAMINE can send technical experts to the site to help you install and debug the equipment on site to ensure smooth operation.

Spare Parts Availability

Spare Parts Availability

Setup comprehensive spare parts inventory, providing essential components such as jaw plates, liners, conveyor belts, bearings, hydraulic parts, and more.

Customized Crushing and Screening Solutions

Customized Crushing and Screening Solutions

According to the basic information of your crushing project, our engineer will give you customized crushing and screening solutions.