materials with hardness ≤9

Ball Mill Models

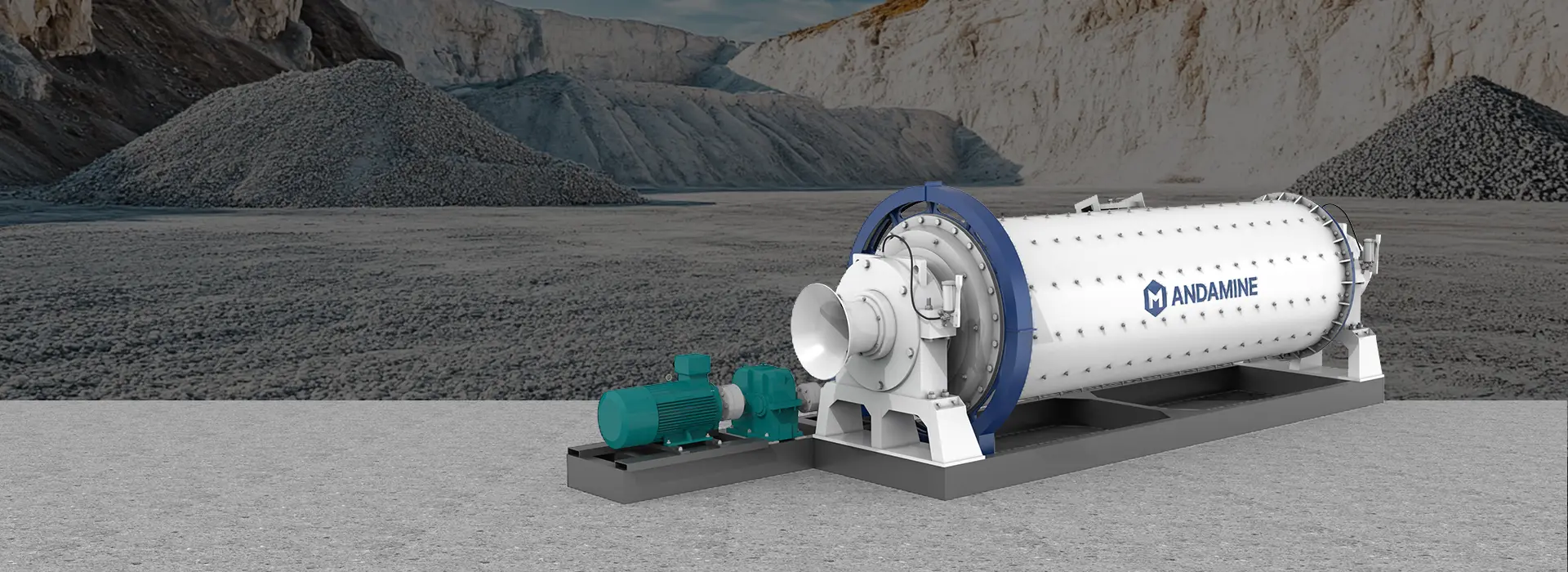

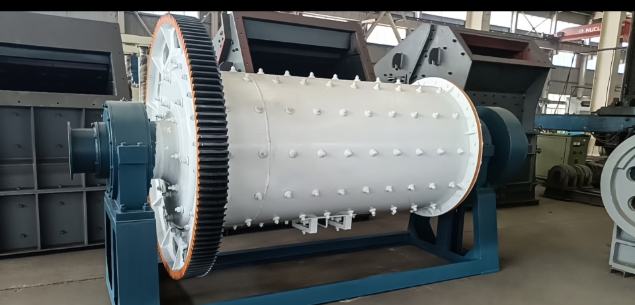

ANDAMINE grinding ball mills are designed as vital equipment for efficient material processing following the crushing phase. This versatile machinery is widely utilized in various industries, including cement, silicate production, new-type building materials, refractories, fertilizers, glass ceramics, and non-ferrous metals. Our ball grinding mill is specifically engineered for high-performance grinding, ensuring consistent and uniform particle size reduction, which is crucial for effective material usability. It effectively processes a diverse range of materials, including gold ore, marble, feldspar, quartz, calcite, limestone, copper ore, and iron ore, making it an invaluable addition to any production line.

Ball Mill

- Suitable for grinding gold ores, iron ores and other materials

- Applied in the chemical industry, electric power, cement, silicate products

Feed Size:≤25mm

Processing capacity:1-100t/h

Finished Product:0.047-0.5mm

Get A Quote >

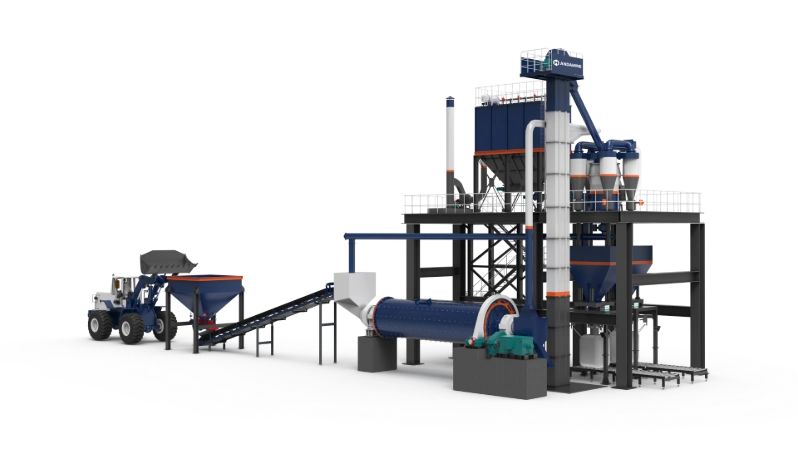

Ball Mill Grinding Line with Air Classifier

- Applicable to various industrial grinding projects.

- Customized ball mill solutions for global customers.

Processing Capacity:20-386t/jam

Finished Product:0.074-0.89mm

Get A Quote >

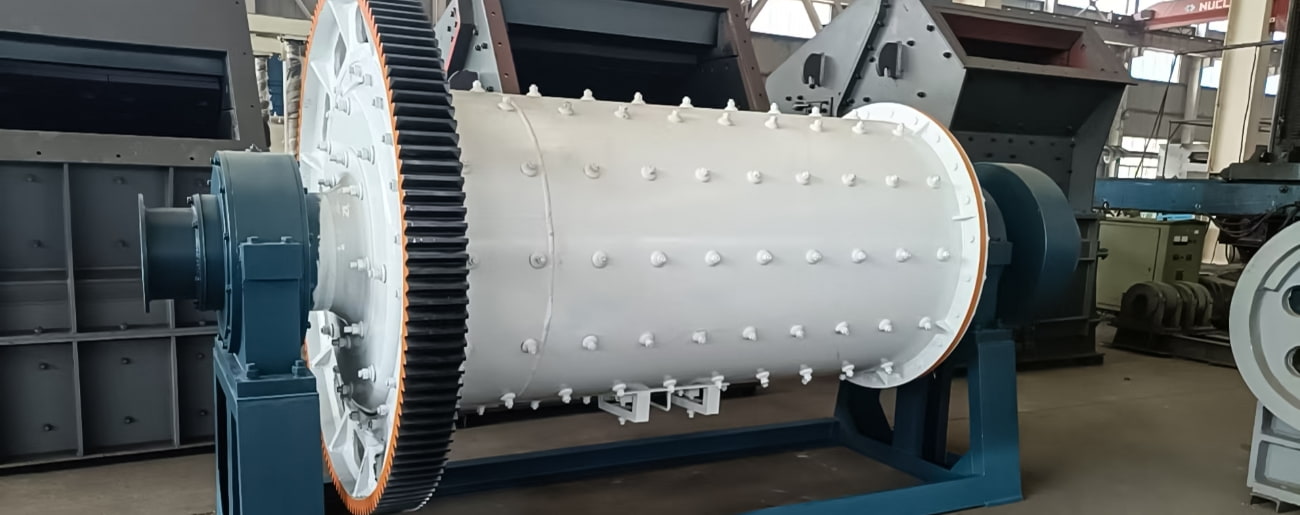

Characteristics

Energy Consumption

Low starting current and flexible starting;It uses rolling bearings instead of the original sliding bearings, it reduces friction, energy consumption and saves more than 30% of electricity;

Increased Production

ANDAMINE energy saving ball mills are equipped with rolling bearing supports instead of tile sliding bearing supports, the energy saving is 10-20% and the production capacity is increased by 10-20% with the same power;

Running Smoothly

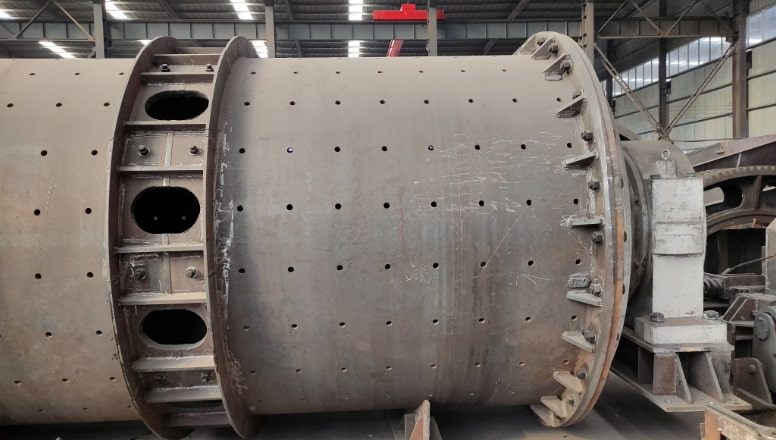

The cylinder adopts automatic welding, ultrasonic detection, overall annealing and other measures to make the equipment run smoothly and with high efficiency.

Parameters of Ball Mill

| Model | Rotate Speed (r/min) | Grinding Media Weight (T) | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (T) |

|---|---|---|---|---|---|---|---|

| Φ900×1800 | 36 | 1.5 | ≦20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.5 |

| Φ900×3000 | 38 | 2.7 | ≦20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.7 |

| Φ1200×2400 | 36 | 3 | ≦25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200×3000 | 36 | 3.5 | ≦25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1500×3000 | 32.4 | 7.5 | ≦25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500×4500 | 29.7 | 11 | ≦25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1830×4500 | 25.4 | 15 | ≦25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830×7000 | 24.1 | 23 | ≦25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100×3000 | 23.7 | 15 | ≦25 | 0.074-0.4 | 6.5-36 | 155 | 34.8 |

| Φ2100×4500 | 23.7 | 24 | ≦25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2200×4500 | 21.5 | 27 | ≦25 | 0.074-0.4 | 9-45 | 280 | 51.8 |

| Φ2200×7500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400×3000 | 21 | 23 | ≦25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400×4500 | 21 | 30 | ≦25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700×4500 | 20.7 | 48 | ≦25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200×4500 | 18 | 65 | ≦25 | 0.074-0.4 | 25-120 | 630 | 137 |

| Φ3600×4500 | 17 | 90 | ≦25 | 0.074-0.4 | 25-140 | 850 | 158 |

| Φ3600×6000 | 17 | 110 | ≦25 | 0.074-0.4 | 25-160 | 1250 | 175 |

| Φ4000×6000 | 16.9 | 146 | ≦25 | 0.074-0.4 | 65-248 | 1600 | 218 |

| Φ4500×6400 | 15.6 | 172 | ≦25 | 0.074-0.4 | 54-306 | 2000 | 280 |

Global Projects

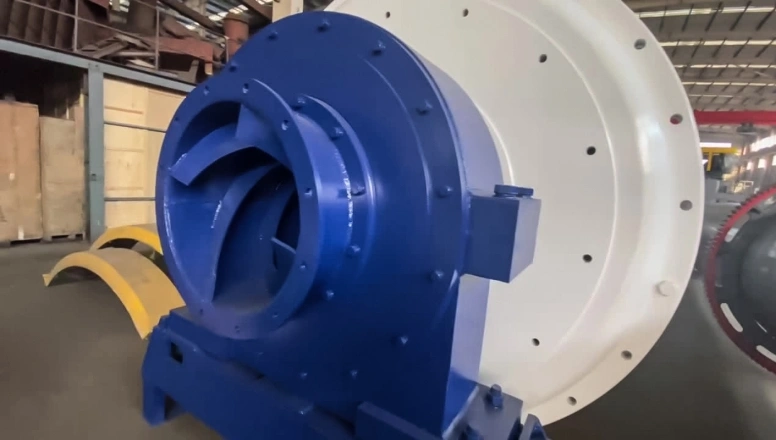

12.5t/h Ball Mill Ready to be shipped to Indonesia

Project Time: Nov. 2024

Raw Materials: Limestone

Finished Product(mm): 200mesh

Application: Cement production

Project Location: Bawu Bawu

Get A Quote >

5t/h Ball Mill Running Well For Gold Processing

Raw Material: Gold Mine

Capacity: 5t/h

Time: Nov. 2022

Application: Refining gold

Get A Quote >

Ball Mill For Gold Processing

Raw Material: Gold Ore

Capacity: 40t/h

Balls: Steel balls

Get A Quote >

ANDAMINE Service

Factory Direct Sales & Quality Assured

We have professional technical team and provide installation and maintenance support to our customers globally.

Spare Parts Service

Spare Parts Service

We have after-sales service team to solve our customers’ problems about spare parts. We provide fast and convenient spare parts service for globally customers.